CASE STUDY > JSW GROUP

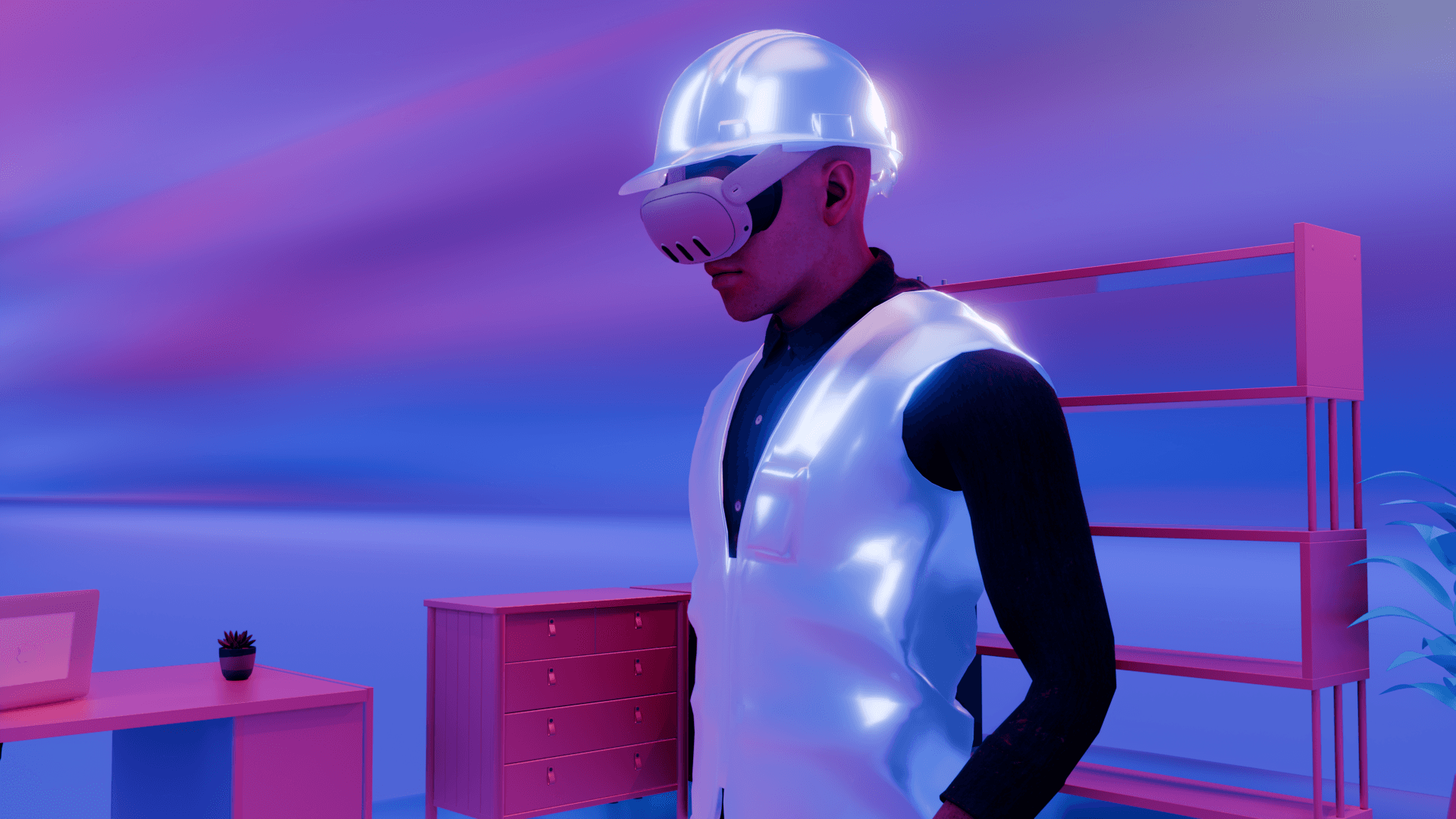

Standardizing VR Training at Scale with JSW Steel

The VRseBuilder ROI

Standardized training across 6 steel plants

Performance-tracking & analytics

Sporadic & haphazard safety education

Why did JSW choose AutoVRse’s VR training?

In a span of mere 45 days, the first module was created end-to-end using VRseBuilder

Multi-Lingual

Support

A diverse workforce necessitated that the module support voiceover, textual instructions, and evaluation in multiple languages

Consequence-

Based Learning

Simulated real-world scenarios, showcasing to the workers the consequences of inaction and inattention during critical scenarios

Cloud-Based Deployment

Centralized deployment on-cloud to manage and update data, to ensure one standard training across multiple plants

Hand

Tracking Controls

The tech-illiteracy rampant among target users ruled out the use of controllers. Hence defaulting the controls to hand-tracking was critical

JSW safety journey

key moments

Conveyor Belt Safety Module Creation

The first safety module was completed in just 45 days

The initial focus was on high-risk conveyor belt operations

Implemented consequence-based learning scenarios, for a thorough inference of the learning material by the target users

Rapid Multi-Plant Deployment

Deployed training in 6 JSW steel plants within 2 months

Procured 6 VR headsets for each plant

Future Expanded Rollout

Initiated development of 59+ additional modules including both safety and process training

Set a goal to train 100,000+ workers by March 2025

Expanding to other sectors including Port and Energy